Description

You’ve spent years and thou$and$ on your Dream Machine ! Do you imagine flying your Pride and Joy with a Military Style Stick Grip ( from either seat ), or with other attempts at making a stick grip, such as using just a soft bike grip, ski pole handle or dowel rod that you stuck a couple of cheap switches in, which would be labor intensive to make and wire at best, that turn ON ( make contact ) if you bump them 1/200th of an inch ( our Stick Grip switches WILL NOT do this ), and that the only way to mount it is to glue it on ( then always wondering not if, but when, it will come off ) ?!?

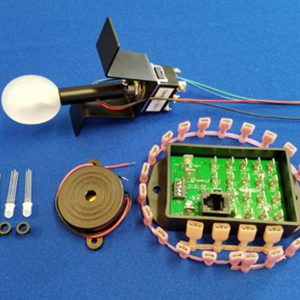

Our Military Style Stick Grips (HOS) — that are standard issue in our Infinity 1 Quick Build Kit Sport Aircraft — are a high quality original, similar to the grip used in the F-4 Phantom, F-15 Eagle, A-6 Intruder, Cobra Gunship, Bat Plane, SeaQuest, etc., but is about 0.5″ shorter and a little smaller in girth than the military versions to better fit the average size human hand without a glove, and has 6 individual Switches ( 9 switches total ) controlling 9 to 13 Functions — no other Stick Grip for Sport Aircraft in the world can control this much !

Thousands have already been installed in hundreds of makes and models of aircraft world wide since 1992 ( even a 314 foot custom Yacht, and several 1 and 2 man submarines ! ). FAA certified in the Adam Aircraft, Micco and Eagle FAA certified aircraft. Field approved in Brantly, Bell 206, Hughes 500, Enstrom, Hiller and most other helicopters ( but not the Robininson ), Aero Commander 500 A’s, Mooney’s, Cessna’s, Swifts and in blimps. Standard issue in several of today’s finer Sport Aircraft Kits, such as the Thunder Mustang. Can be seen in the prototype Piper Jet, Viper Jet, Express, Legend, Sherpa, Lionheart, Rutan Boomerang, Maverick Twin Jet, Carter Copter, Adam Aircraft, Eclipse 500 ( and their cockpit demo ), Jim Dunn’s Fuel Cell powered E-Plane, John Sharp’s Nemesis NXT, Dick Rutan’s beautiful red, white and blue Berkut, Wayne Lanza’s Velocity, Jeff Auckland’s Radial Rocket, Brian DeFord’s Blonde Streak, Greg Richtor’s Jet Cozy III, Grant Nicholls’ Jet Long-EZ-RG, Lance Hooley’s Jet Long-EZ, Steve Wright’s StaggerEZ , and many, many others. Also, installed in Wayne Handley’s turbo-prop powered Turbo Raven air show demonstration plane ( see cover story of April ’99 issue of Sport Aviation magazine, page 22 ), in Duane Upton’s Swift of the Swift Magic Team, and in Bill Cherwin and in Gary Donovan’s yellow T-34 of the Lima Lima Flight Team. Can be seen in the Cafe Foundation article about Mark Beduhn’s Cozy MK-IV ( ‘Sport Aviation’ April ’99 issue, page 59 ), in Jean Prudhomme’s Velocity shown in the April ’99 Kitplanes article page 7, and in Bob Warner’s article on page 95 in Sport Aviation’s July ’99 issue, and in many other articles and pictures of aircraft in many magazines. In fact, our Stick Grips are in someone’s featured aircraft, and/or in an ad, in just about every flying magazine these days, whether our Stick Grip is specifically mentioned and/or pictured, or not. Also, installed in military planes such as T-38’s, Mig’s, CJ-6A’s, T-6/SNJ’s, P-51’s, L-39’s, Yaks’s, Marquette’s, and more. Select custom instrument panel manufacturers provide only our Stick Grips as standard issue with all their custom panels. Used in simulators at Edward’s AFB, the FAA in Oklahoma City and the Navy in Texas, Wright Patterson AFB, and Eclipse 500 sims, and by NASA to control their UAV’s ( Unmanned Air Vehicles ) ; sims made in Canada, sims made in Europe, sims made in Austria, sims made in New Zealand, Swiss Brunner Sims, and sims made in Australia. Used in crop dusters and turbine ag planes; by the US Post Office controlling robot arms to pick up huge mail boxes to put them through GAMA Radiation machines to kill Anthrax after 9/11 ; for SWAT bomb retrieval robots ; used by the Worlds Fastest Female on a motorcycle ; to control electric wheel chairs ; to drive handicapped vans ; Toyota Camry engine assembly line machining ; Ford Motor Company in a futuristic car ; fire trucks to aim and shoot the foam nozzle and operate other accessories ; to drive and control Principia’s Solar Car; as a shifter in Corvettes, jeeps, Ford F-150, 2005 Mustang, race-modified 2002 Toyota Celica GT-S Supercharged car, and off-road vehicles, controlling CD players, Nitrous Oxide, smoke and various other vehicle systems / functions ; controls the bug pincers in the movie Starship Trooper, can be seen near the beginning of the movie Miami Vice in the Adam 500, 1+40 minutes into the movie Oblivion you can see 2 right hand Stick Grips, Batman has a left Stick Grip in Batman vs Superman, 3 Stick Grips in Fast & Furious 8, Transformers Bumble Bee, and Open World ; Virtual Reality ( VR ) games and simulations ; Aces Flight Simulators that was at the ‘Mall of America’ for 13+ years; used on a Caterpillar Excavator for the Harlem River Tunnel ; and many, many thousands more!

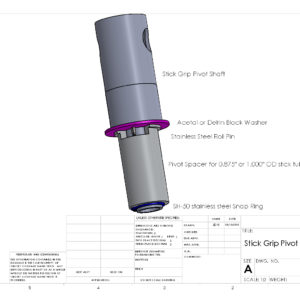

Remember, our Stick Grips are ***NOT*** glued on or held on with just a set screw, but they *clamp* over the top of your stick tube with a screw through your stick tube. See Installation Drawing.

INFINITY Aerospace designed this Stick Grip with safety, comfort, functionality and durability in mind for our Infinity 1, that also fits all aircraft. The anatomical ergonomic design is contoured to the shape of your fingers, and includes a fatigue reducing hand rest at the base. Made from a high impact and flame retardant material. The non-glare black finish is abrasion and impact resistant for long life, yet easily repairable. Stick Grips and Throttle Handles with switches built into them ( both used together are called a HOTAS system ), should be standard issue in ALL aircraft for they greatly reduce pilot workload, increase pilot efficiency, de-clutter the instrument panel, and make flying the aircraft much safer, among other things. But note: OUR Stick Grips also have ergonomically located switches so they cannot be accidentally bumped ( unlike some other stick grips and home computer joy sticks ), yet are still easily reached.

Definition INFO:

The term “HOTAS” is used in the military and airline worlds, and stands for ‘Hands-On-Throttle and Stick’. Also, JD came up with the terms “HOT” which stands for ‘Hands-On-Throttle‘, and “HOS” which stands for ‘Hands-On-Stick’.

A Few More Definitions:

VDC = Volts Direct Current ; PSI = Pounds per Square Inch ; GPM = Gallons Per Minute ; LPM = Liters Per Minute ; AMP = Amps or Current ; CB = Circuit Breaker ; N.O. = Normally Open ; N.C. = Normally Closed ; S & H = Shipping and Handling ; CA = California

News — EAA Oshkosh 2014 Grand Champion Bill Ford’s Legacy RG has our Stick Grips. PLEASE NOTE: Most all Grand Champion and Award Winning aircraft at an airshow have our Stick Grips.

News — As of May 20th, 2004, our Stick Grips are FAA Certified in the Adam Aircraft A-500 and A-700 ! This is our 4th production aircraft in which to be certified as Standard Equipment.

More News — We now have a threaded bottom for direct War Bird Stick Grip replacement ! It can also be used in ANY aircraft ( LEFT or right hand ) !! Also, we now have a Relay Deck !!!

And More News — Darryl Greenamyer has won the Sport Class Gold at Reno in 2002, 2003, 2004, 2005, and 2nd place in 2006, in his Lancair Legacy, which has our Stick Grip ! In fact, the first 4 planes had our Stick Grips !! PLEASE NOTE: most of the Reno Sport Class Race Planes are flying with our Stick Grips !!!

And Even More News — May 09, 2011: the Northrup-Grumman Firebird is flying with our Stick Grips ( see time stamp 1:04 ) !!!!

And the News Keeps Coming — you can see our Stick Grips in even more movies — Batman vs Superman, Fast & Furious 8, Transformers Bumble Bee, and Open World !!!!!